Anomaly Detection Is the Next Big Thing in Smart Hotels

Written by John Wojnicki

In a hospitality environment, anomaly detection can support optimal operation in many ways—from reservation systems to potential cybersecurity threats. Learn more about why it’s the next big thing in smart buildings.

A smart building is a self-sufficient, data-driven building—all about connecting the physical world to the digital world. It generates its own performance data using sensors, devices, systems and detectors. That information can be used to continuously improve efficiency, comfort and safety.

In gaming and leisure environments specifically, data gives owners the insights they need to empower staff, wow travelers and add value to the right guest touchpoints—all while driving down costs and optimizing maintenance.

When anomalies are detected within the data—inconsistencies that don’t align with normal data patterns or that deviate from established baselines—they can be signs of a potential problem.

Anomaly detection is a way to monitor network and system performance, pinpoint data variability and alert the right person when something falls outside normal operating parameters.

In hospitality facilities, creating a fabulous guest experience is no longer only about excellent service, impressive amenities or state-of-the-art technology. It’s about preventing situations that may negatively impact guests.

Because data anomaly detection uncovers inconsistencies in network and system performance, your team can work behind the scenes to address issues and make sure they don’t turn into larger, more costly problems.

The value of anomaly detection in hospitality

When real-time data from smart building devices and sensors is consistently evaluated, anomaly detection can perceive something as simple as a malfunctioning wireless access point or as complex as an entire system malfunctioning.

If a wireless access point that supports maintenance activity uses the same channel as your hotel’s videoconferencing platform, for example, this could introduce additional network traffic that causes buffering and jitter.

Before users notice these network issues, anomaly detection can identify when network traffic begins to change—by pinpointing an increase in channel utilization on an access point by a certain percentage, for example—and notifies the right people so corrective actions can be taken, if needed.

Machine learning can take anomaly detection to the next level by removing manual work from the equation completely. Performance thresholds can be adjusted based on network activity over a period of time. Based on what’s happening, the network can learn to self-heal without anyone stepping in.

The real world: anomaly detection in action

In a hospitality environment, anomaly detection can support optimal operation in many ways.

- Reservation Systems: Anomaly detection algorithms can analyze reservation data to identify irregular booking patterns, such as a sudden influx of bookings from unusual sources or an abnormal number of cancellations. This helps prevent fraudulent activities and protects against reservation system abuse.

- Employee Activities: Anomaly detection can be used to monitor the flow of employee data. For instance, if an employee accesses sensitive guest information outside their regular work hours or attempts to extract large amounts of data from the system, then this could indicate unauthorized access or data theft.

- Potential Cybersecurity Threats: Monitoring network traffic within the hospitality space is essential to identify any abnormal activities that may indicate cyberattacks or data breaches. Anomaly detection algorithms can analyze network traffic patterns, detect unusual data transfers or communication patterns and raise alerts for potential security threats.

Improve the guest experience in new ways

By identifying and addressing anomalies promptly, gaming and leisure organizations can safeguard operations, protect customer data and maintain a high level of trust and satisfaction. This allows you to prevent problems and improve the guest experience in ways never possible before.

Belden can help you create high-quality data acquisition, transmission, orchestration and management solutions that support your innovative hospitality technology initiatives—including anomaly detection.

Learn more about how we can help you integrate technology and anomaly detection into the guest experience.

Find the original article here

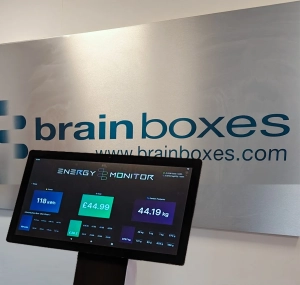

Wherever you are on your digital transformation journey, data visualisation makes it easy to optimise operations.

Wherever you are on your digital transformation journey, data visualisation makes it easy to optimise operations.